Preface

I purchased my first standup jeksi earlier this year and, man, was it a great purchase! I’ve ridden sitdown jetskis throughout my entire life but never had the chance to ride a standup. Jumping the wakesurf boats wake is a ton of fun.

I accidentally clipped the bottom of the hull on the boat dock when returning from a quick day session during the summer and made a hole in the hull. It was a slow leak but still needed repair.

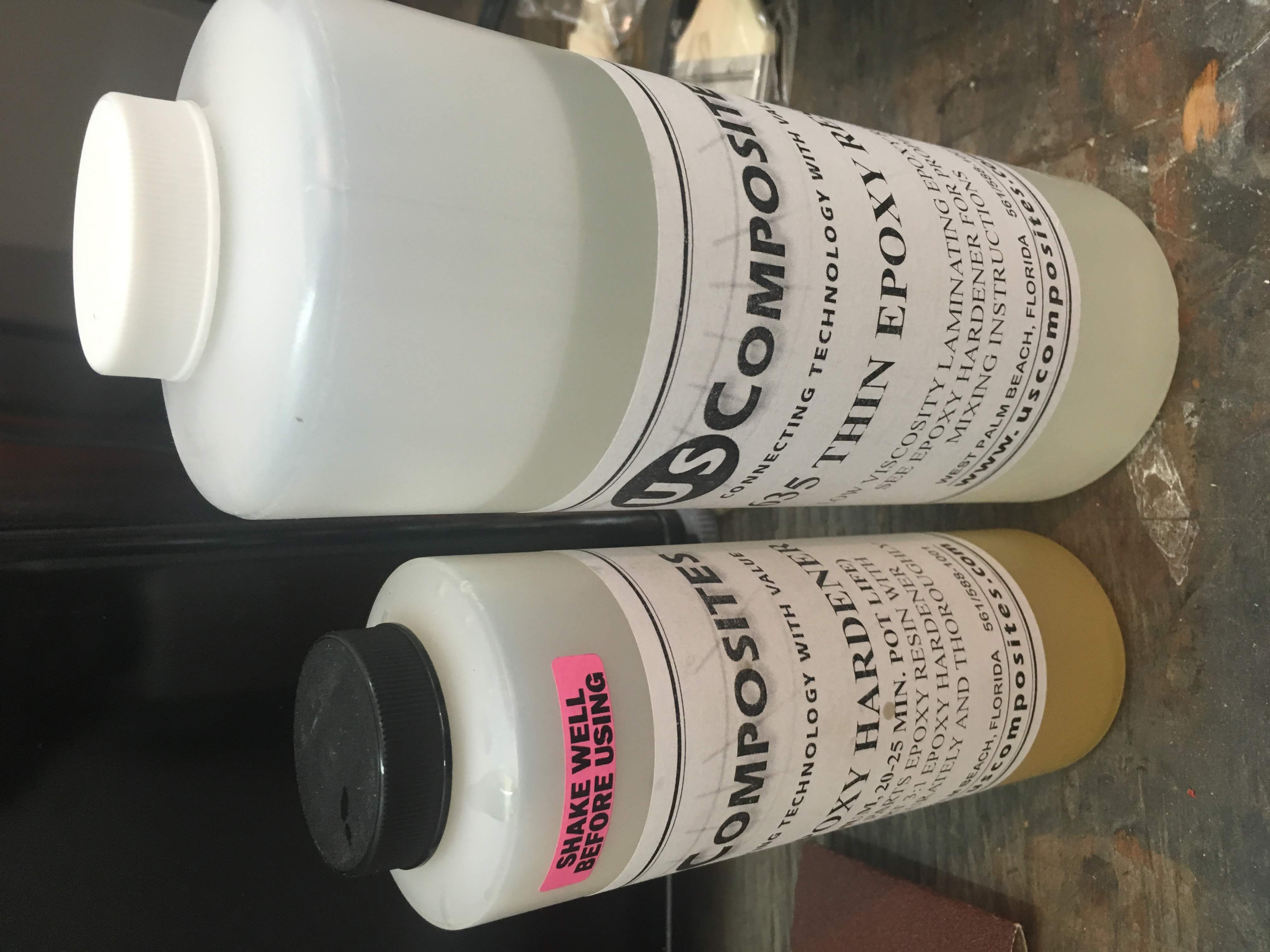

Materials

US Composites makes high quality epoxy resins and fiberglass mat at a low cost so that was used for the repair. Check out the links to their site for both:

US Composites 635 Thin Epoxy Resin

US Composites Fiberglass Mat

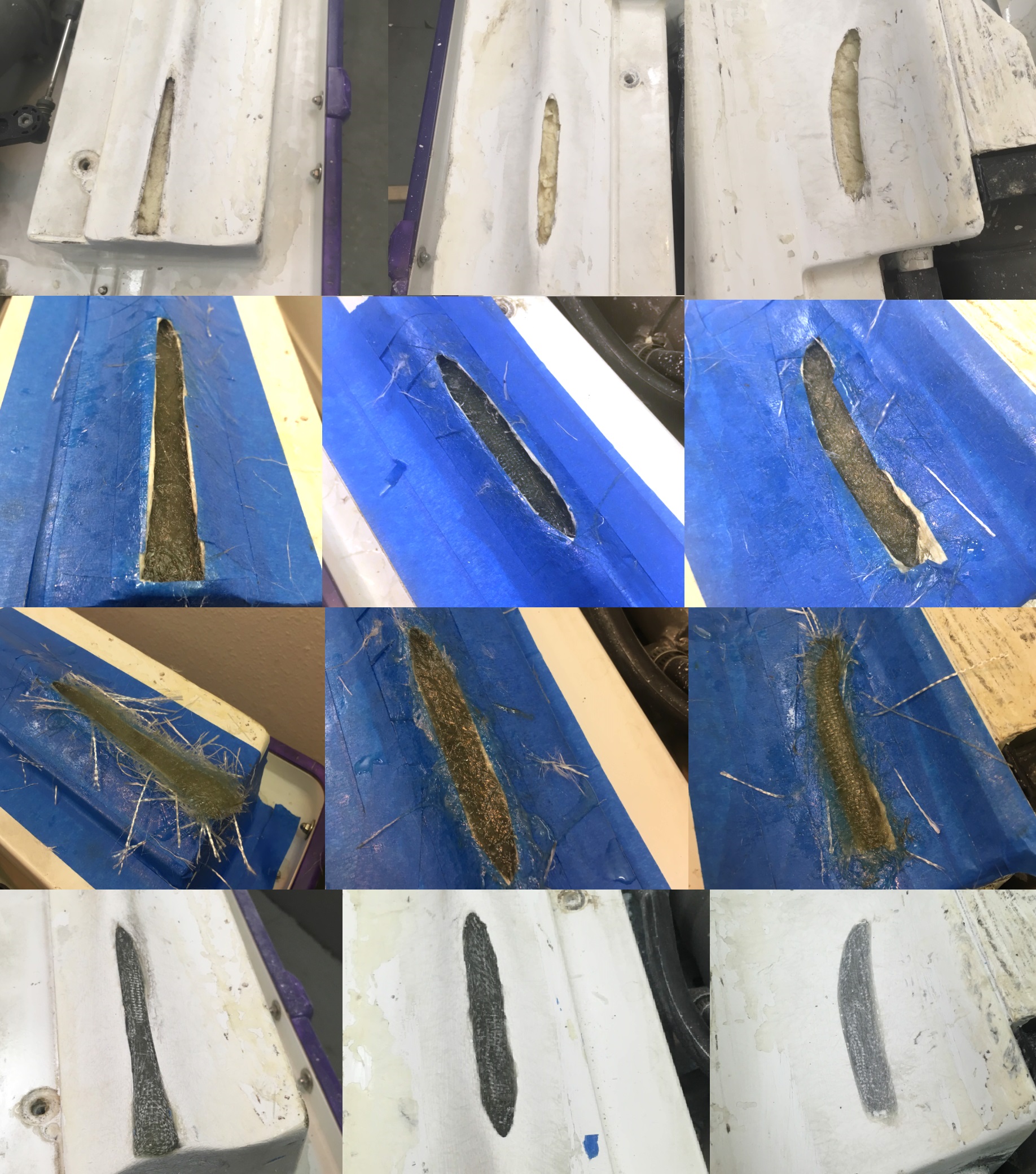

Stage 1 Repair

The first part of the repair process was to remove any rotted fiberglass from the area with the damage using a random orbital sander with 80 grit paper. There is foam inside the hull so a bit of that was removed to make area for laying the fiberglass mat. Next, the mat was placed inside the damaged areas, wetted and sanded, in stages until new fiberglass grew out of the hull.

Stage 2 Repair

Fiberglass mat was then sanded down around the damaged areas further to allow for mat to be applied over the top of the area. It is important to taper the edges near the damaged areas to allow for the fiberglass mat to build up at an angle - to adhere well to the hull.

The areas were then sanded and contured to the shape of the hull.

Stage 3 Repair

The last process of the repair was to apply gelcoat to the raw fiberglass. This was also done using US Composites materials. I do not have any documentation or pictures of this process - sorry! But here is a link to the products: